Design and Function Requirements for Aircraft Interior Materials

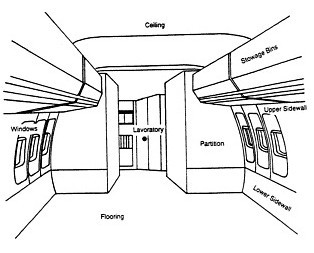

For the purposes of this study, the interior of an aircraft is considered to be everything that is contained inside the pressure shell, that is, the pressurized part of the aircraft fuselage. The regulatory requirements of Federal Aviation Requirements (FAR), Part 25, that apply to interiors fall in FAR 25.853, Compartment Interiors, and FAR 25.855, Cargo or Baggage Compartments. Although FAR 25.853 has the introductory terms ''For each compartment occupied by the crew or passengers, the following applies,'' items that ate not strictly in the occupied compartment (i.e., are outside the cabin liners and not visible to either crew or passengers, such as "electrical conduit, thermal and acoustical insulation and insulation covering, air ducting," are specifically cited and the regulatory requirements are also applied to them. Interior cabin liner components are identified in Figure 2-1.

An aircraft interior is designed to meet the requirements of:

the FAA and other regulatory agencies,

the airlines,

airline passengers, crew, and

the aircraft manufacturers.

There are minimum requirements that emanate from these four groups, which together comprise the design criteria. Issues to consider in the development of combined (inclusive) design criteria for aircraft interiors are shown schematically in Figure 2-2.

The safety criteria include the FAA regulatory mandates, which address only safety and axe largely quantitative. However, there are other, nonregulatory requirements such as passenger comfort level that are difficult to quantify, which complicates the task of the designers. Aircraft interior design is further complicated by the fact that many of these needs compete with each other and thus trade-offs are necessary.

Once the design of a part has been established by design engineering organizations, and once drawings describing the design and manufacture are released to the manufacturing organizations, many business processes are activated to car out acquisition of materials (inventory), tools, facilities, and manpower. If a subsequent change is made to the design, all the manufacturing planning is also subject to change, which can be time consuming and costly and creates the potential for a substantial economic penalty. There is, therefore, a strong priority assigned to designing parts "right the first time."

MATERIALS OF CONSTRUCTION

The current state of the art for materials used to make parts that satisfy the design criteria and other requirements fall into several main categories or families. Materials categories that could be used to fabricate more fire-resistant interiors would be subject to the same selection and use criteria.

Currently, most of the vertical and ceiling surfaces of aircraft are comprised of sandwich panels fabricated from face sheets of phenolic resin and fiberglass or carbon fiber reinforcement, and a polyaramid (Nomex®) core. These panels are covered with highly formable decorative thermoplastic films that are printed in a variety of complex patterns and

Figure 2-1 Aircraft interior cabin liner components. Source: FAA (1990).