The 3D-MID research association holds biannual awards and in May 2011 the industry category was won by the Bosch DS8 pressure sensor. This device, which converts hydraulic braking force into an electrical signal, is part of Bosch's electronic stability programme braking control system for vehicles. Bosch makes more than 10 million DS8 sensors per year.

A key part of the DS8 is the two-component MID produced by moulder PKT Präzisions-Kunststoff-Teile in two Ticona liquid crystal polymer (LCP) grades. One LCP is a standard Vectra E 130i; the other is Vectra E820i Pd - a palladium catalytic, 20% mineral filled and modified LCP, on which surface tracks are selectively plated with copper, nickel and gold layers by Collini.

The MID functions as a carrier for a circuit board, providing conductive tracks between the sensor element and the circuit board, as well as from the circuit board to the unit's contacts. A highly miniaturised MID design enables the DS8 to be used in all new braking control systems.

In the awards, 2E Mechatronic won the innovation category for a flow sensor MID for air conditioning systems. This sensor chip carrier is made in 40% mineral filled Vectra E840i LDS and its tracks are plated after LPKF laser equipment is used to selectively activate the laser sensitive additive in the LCP plastic. Production volume amounts to around 20,000 parts/year.

The company worked on this "HybridFlow" thermal membrane chip-based sensor project with relay and switch specialist Gruner, research institute HSG Hahn-Schickard-Gesellschaft and micro-sensor developer MicroMountains Applications.

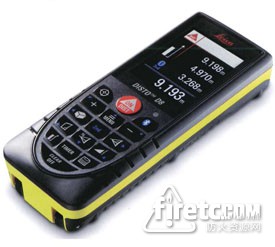

Capacitive tilt angle sensors also use MIDs. In this field, 2E Mechatronic worked with HSG and MicroMountains in the "Femikanes" project. In this project, the partners developed a fluid-based, thermally compensated 360° sensor for the Disto D8 distance measuring device made by Leica Geosystems.

Another version of this MID can be used in applications such as controlling the positioning of solar panels.

2E Mechatronic has developed a laser structured MID-LED light component for dental lamps in Vectra 840i LDS. The company also sees potential for using MID-LEDs in automats, and house and street lighting.

Harting Mitronics continues to develop new MIDs. A recent one is a camera module MID with a Vectra 840i LDS substrate for the Sick V300 Work Station camera.

Harting Mitronics has been using a Lanxess Pocan PBT grade to produce RFID transponder MIDs. Lanxess refers to material tests showing Pocan DPT7149 LDS has the ability to withstand a vapour phase condensation reflow solder temperature of 280¡C in the short term.

In September, Harting announced it had developed a solder with a low melting point (138°C), enabling the wider use of thermoplastics such as PBT and PC/ABS.

Some thermoplastics producers have risen to this opportunity by developing lower temperature thermoplastic grades for laser direct structuring (LDS) in a range of colours. These provide more aesthetic design freedom for MID exterior surfaces.

In June, Sabic Innovative Plastics launched LNP Thermocomp NX11302 (a PC/ABS blend); in July, Mitsubishi introduced Xantar LDS 3723 (also PC/ABS) and LDS 3733 (PC).

In another development that widens the use of MID materials to ABS and PC/ABS, LPKF announced in September that plating specialist MacDermid has developed an electroless copper plating system. The MID Copper 100 B1 process replaces the two-step common initial (strike) and full build plating stages with single-stage 2D-MID LDS plating. This process is said to cut plating costs by around 20%.

3D MID from 2E Mechatronic