1.Low thermal expansion

2.High filter specific surface area

3.Low pressure drop

4.Long-term durability performance

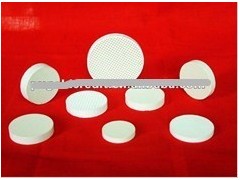

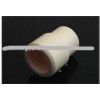

Honeycomb Ceramic Filter Plate

Introduction: With excellent thermal shock resistance, high strength, high hole fraction and specific surface area, unique cell designs and advanced material used to make our Extruded Ceramic Filters have a special function of attracting and capturing molten metal impurities on the cell internal walls.

are available in a range of cell sizes for Foundry & Casting applications. A wide choice of filter dimensions is also available to answer any gating system requirement.

Advantage:

Good quality;

Improved machinability of castings;

Increased pour rate;

Improved machine tool life

Material: Cordierite, Mullite, Cordierite/Mullite.

|

Items |

Parameters |

|

Porosity(%) |

80~90 |

|

Max. Operating Temperature(°C) |

1550 |

|

Bulk Density (g/cm3) |

0.7~1.8 |

|

Compression Strength(Mpa) |

>15 |

|

Thermal Shock Resistance(times/1100°C) |

>6 |

|

SiO2(%) |

38~42 |

|

Al2O3(%) |

53~57 |

|

Fe2O3(%) |

<1.5 |

|

TiO2(%) |

<1.5 |