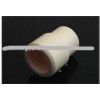

Specialized mfr. of 70% porcelain ball;

High hardness, wear-resisting, high efficiency;

Ideal grinding media for ball mill

Zhonglian Featured product----70% porcelain ball

Production Technology: advanced spray drying technology,

dry type full automatic iso-static pressure process ,

high temperature roller kiln sintering technology

Size: 30mm, 40mm, 50mm, 60mm

Usage: grinding materials

Advantages:

Compared with natural stone balls and normal ceramic balls, alumina grinding ball increases by 20-40 times in its performance of wear resistance. Its grinding efficiency improves by 40%-60% and ball mill efficiency add by 30%-40%. Their total costs only take 40-60 percent of that of natural stone balls.

Superiority:

· professional manufacturer of ceramic grinding media

· large area of factory with forty thousand square meters in total

· complete sets of high-tech equipments

· offer different types and sizes of products, which are featured by high hardness, high density, low wear loss and good corrosion-resistance

Technical data:

Al2O3 content 70%

|

Physical Properties |

Chemical Properties |

|||

|

Item |

Unit |

Index |

Content |

Index |

|

Bulk Density |

G / cm3 |

≥3.0 |

Al2O3 |

68-70% |

|

Wear Loss |

G / kg.h |

<0.25‰ |

SiO2 |

15-20% |

|

Water absorptions |

% |

<0.02 |

Fe2O3 |

<0.5% |

|

Mohs Hardness |

Scale |

>8 |

others |

4.5% |

|

Specifications |

mm |

30-60 |

||

|

Color |

Ivory |

(with TiO2) |

||