1. Professional manufacturer for 15 years;

2. Bamac grains;

3. Reliable supplies;

4. Prompt delivery (7 days for 1000MT);

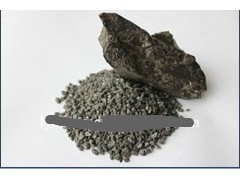

Brown Fused Alumina

Brown fused Alumina known as “artificial corundum” or “alumina grit”. Brown fused alumina is produced from bauxite, charcoal, iron chip by being fused under high temperature in an electric arc furnace. It is characterized by high toughness and has a micro hardness of 2000-2200kg/mm2. The abrasive tools made by brown fused alumina are suitable for grinding carbon steel, normal alloy steel, malleable cast iron and hard bronze, etc. Brown fused alumina can also be used for making fine quality refractory etc.

Brown Fused Alumina (refractory)

|

Grit Size |

AL2O3 MIN |

SIO2 MAX |

TIO2 MAX |

Fe2O3 MAX |

|

0-50mm |

94.50% |

0.80% |

2.23% |

0.35% |

|

0-1mm |

95.50% |

0.70% |

2.23% |

0.25% |

|

1-3mm |

95.75% |

0.66% |

2.18% |

0.23% |

|

3-5mm |

95.90% |

0.60% |

2.15% |

0.21% |

|

5-8mm |

96.00% |

0.50% |

2.10% |

0.18% |

Physical Performance Index

|

Item |

Index |

|

Color |

Brown |

|

Crystal shape |

Trigonal |

|

Hardness(mohs) |

≥9.0 |

|

Melting Point (°C) |

2250 |

|

True density (g/cm3) |

≥3. 90 |

|

Linear Expansion Coefficient(0—1600°C) |

7—9 |