high softening point, high hardness, rapid drying, plumpy Mexican film, glossiness strong.

Phenolic resin of modified gum rosin for printing ink

De

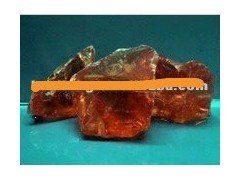

This series of products is a kind ofirregular transparent solid which condensed by stable rosin and alkyl phenol and formaldehyde, adding polyolesterification, through vacuum system and special treatment.

Specification:

|

Type |

octyl-phenolic resin of modified gum rosin |

nonyl-phenolic resin of modified gum rosin |

butyl-phenolic resin of modified gum rosin |

|||

|

type |

BX-855 |

BX-865 |

BX-868 |

BX-872 |

BX825/BX-835 |

|

|

surface |

auburn solid |

puce solid |

auburn solid |

|||

|

acid value(mgKOH/g) |

18max |

8-12 |

15-25 |

8-12 |

18max |

|

|

color(G#) |

8max |

8max |

16max |

8max |

8max |

|

|

solubility |

n-heptane |

8min(ml) |

6-9g |

16-25(ml) |

9min(ml) |

11min(ml) |

|

isopropanol |

6max(ml) |

2-4g |

5.5-7.5(ml) |

5max |

7max |

|

|

softening point, |

150-160 |

160-170 |

160-170 |

150-160 |

120-130 |

|

|

appliance |

top grade inks, adhesive |

top grade inks |

plastic film |

|||

|

packing |

intertexture bag:25/300/500kgs each bag |

|||||

Performance

Solubility outstanding products, and vegetable oils such as linseed oil ideal compatibility with high softening point, high hardness, rapid drying, plumpy Mexican film, glossiness strong.

Application extent

Widely used in high-grade printing inks, recess printing inks and lithographic printing inks and CIP4 etc.