Introduction of Perlite Fire board:

Perlite is known as rock, which is a kind of lava after cooling. People name it perlite due to its fissuring structure of genuine pearl.

Perlite fire board is mainly made of perlite grains which has been expanded rapidly through hige temperature. Meanwhile glassfibre and some inorganic adhesives are added to strengthen its density and fire protection. The board is produced through computer machines with latest industrial technology and advanced production equipment. High temperature, pressure and necessary maintenance are great help to its high quality.

The product owns patent of strength in China mainland and Taiwan area, and effect of fire proof is high after moulding. The main features of the board are good fire-proofing, sound and heat insulation. Its fine fireproofing performance has passed testing of Institution of Tianjin Fire-fighting and Beijing Construction Research Institute. Temperature of back side board is no more than 120`C under testing 45mm thick door core, inside wall and etc.

Characteristic features:

1. Fire proof:

The board has been awarded A1-class fire resistant. Because of its raw material, perlite grains, expanded rapidly through high temperature over 1400`C.

2. Water proof and non-corroding:

Due to its natural and inorganic materials, the board can keep its original shape and strength without any deformation or expansion even after dipping in water for long time.

3. Rustless:

As stated above, our product is pressing-made under high temperature and pressure, and moisture content is strictly controlled between 6-8%, while domestic standard is less than 10%. However, the issue of rustiness in steel door or galvanized steel sheet was unable to solve due to high moisture content while traditional processing.

The fire board is non-corroding to wood or metal.

4. Lightweight and high breaking strength:

Size of perlite grain is expanded around 30 times after high temperature, which makes the board very light in weight. Density of the board is around 280-400kgs/m3. However, strength is much high. Eg, weight of 10mm board is only 10.07Kg/m2.

5. Stable in measurements and non-deforming:

Tolearance of thickness is less than 0.5mm. Perlite board is made of perlite grain, inside which there are plenty of tiny air hole, keeping door in good shape.

6. Cost saving:

The board can be used very conveniently, such as cutting, nailing, drilling, and planning etc. also, it can be assembling very easily, saving much cost.

7. Logo embossing:

Through our one-punch forming, fire product is finished according to client design, which reduces a lot of handwork comparing old ways and fill a gap both domestic and abroad at present. There is no need to machine on it like grooving and routing and etc.

8. Green and environmental protection:

The board is made of natural materials, which is green and harmless to envirment.

Content and specification:

- Contents: 85% perlite grain, 5% glass fibre mesh, 5% plaster, 5% other inorganic materials.

- Production specification: 900*2100, 1150*2250mm with thickness 30mm, 36mm, 40mm, 43mm, 46mm, 48mm, 50mm and etc.

Any size can be produced according to client requirements.

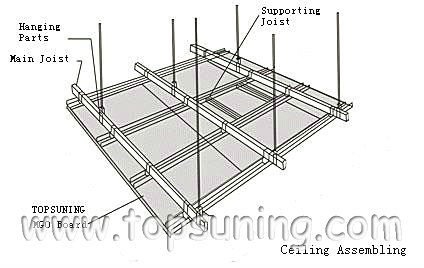

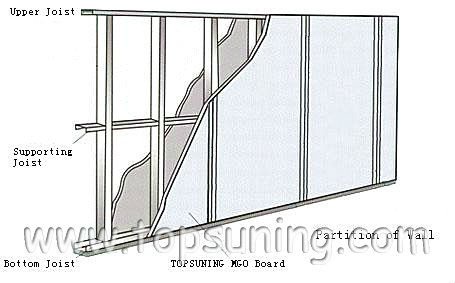

Wide range using of Perlite board:

Due to excellent characteristic features, Perlite board is used widely as steel and wooden door core, partition, inside material of roof and exterior wall, prefabricated house and etc. It is reliable fireproof and aseismatic construction material to be used where house, hotel, shopping mall, factory yard, school, hospital, railway station, airport and etc.

Physical characteristics:

|

Density |

280-400kgs/m3 |

|

Moisture |

6.1% |

|

Heat conduction |

0.088w/mk |

|

Asbestos |

None asbestos is included |

Block Sizes and Dimensional Tolerances

|

Length(±3mm) |

Width(±3mm) |

Thickness(+2mm,—1.5mm) |

|

900 |

2100 |

20—60 |

|

1150 |

2250 |

20—60 |