1.Halogen Free Flame Retardant for Reinforced PBT

2.UL94-V0 (0.75mm) ,850oC Glow Wire,RoHS

INTRODUCTION: EPFR-300A, mainly contains N and P, is a kind of halogen-free greener flame retardant. It was developed especially for the glass fiber reinforced PBT. This flame-retardant functions in the condensed phase and the gas phase. The flame-retardant glass fiber reinforced PBT with EPFR-300A can pass the tests of UL94-V0 (0.75mm) and 850°c GWFI. Moreover, it is free from the restrictions of RoHS Directive 2002/95/EC approved by the EU and the Council. The products with EPFR-300A have the characteristics as less mold corrosion, excellent electrical properties and so on.

INDEX:

RECOMMENDED DOSAGE:

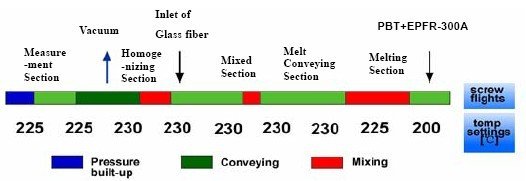

EXTRUSION PROCESS: (Twin Screw Extruder)

NOTES:

(1)The thermal decomposition temperature of EPFR-300A in nitrogen is 280°c. The melting point of PBT is 225°c. The lower processing temperature of twin extruder is needed so as to avoid the decomposition of EPFR-300A. The shear heat of screw extruder of this high level filler system (30% glass fiber + 23% EPFR-300A) is very high, it may lead to the true temperature inside the extruder 20~50°c higher than the set temperature of the screw extruder. This partial overheating inside the extruder may lead to the decomposition of EPFR-300A. The shear of screw combination must be weakened thereby.

(2) Raw materials (resin and glass fiber) must be pre-dried. Make the moisture as low as possible. The machine must be clean whether it is extruder or injector. Make sure that the flame retardant does not stay too long inside the barrel of the machine.

(3)In order to get the smooth extruded sliver, reasonable die pressure should be established. If the pressure is not enough, the sliver will not be extruded continuously. The continuous extrusion of sliver can be realized by adjusting the die temperature properly, increasing the number of long fiber, decreasing the rotation speed of extruder and increasing the amount of feed. All these adjustment must be exerted in accordance with related conditions, e.g. the currency of the machine.

RECOMMENDED SCREW COMBINATION:

APPLICATION EXAMPLES

1. FORMULA:

2.PROCESS TECHNOLOGY:

Model: Twin Screw Extruder 30

The shear numbers before fiber entry: 45°/5/28 4 blocks 90°/5/28 1 block 45°/5/28L 1block

Extruding temperature of main machine(°c): 200 225 230 230 230 230 230 225 225

Rotation speed of main machine: 220~240rpm

3. MAIN PROPERTIES: