2.We are the first company set up producing Aluminum Foam Panel in China

3.fire resistant material

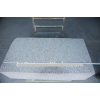

For the production of foamed aluminum, AL powder is mixed with a product releasing gas at higher temperature and then compacted, this foaming agent is placed into a mold form and heated up until the agent starts to foam. Immediately thereafter the mold is taken out of the furnace and cooled off, so the aluminum foam part is frozen in shape. The outcome of this process is a closed cell aluminum foam showing a thin casting skin on the surface.

Property

Heat insulation and resistance, non-inflammable

Absorption of high impact energies,regardless of the impact direction

Highly efficient in sound absorption, electromagnetic shielding and vibration damping

High stiffness at very low density

Application

Aluminum foam (Closed cell) to qualify for specific requirements within the automotive, aviation, railway and engine building industry. Aluminum foam is also qualifying for other high potential applications in the field of Architecture and Design, where electromagnetic shielding, structural damping, flame resistance and a decorative surface structure is required

Size 500*500*6mm 1000*500*6mm 1800*800*10mm

500*500*8mm 1000*500*8mm 1800*800*15mm

1000*500*10mm 1800*800*20mm

1000*500*15mm

1000*500*20mm

1000*500*30mm